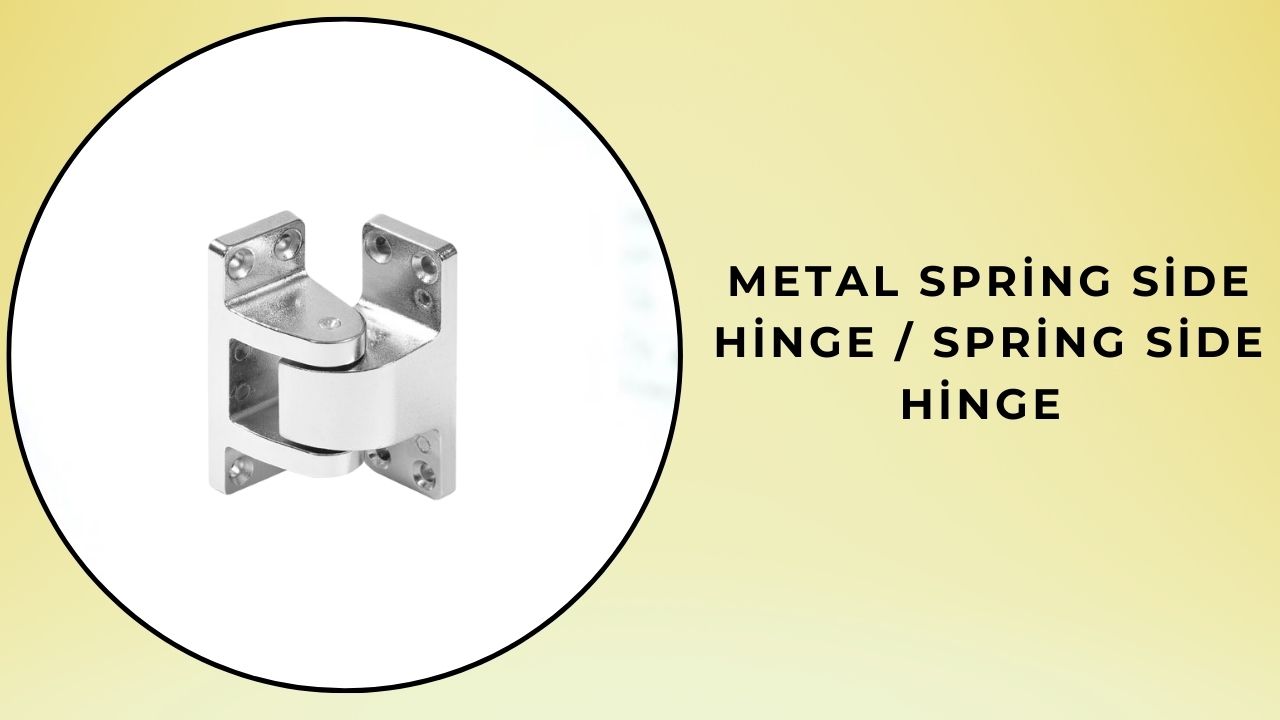

Metal Spring Side Hinge / Spring Side Hinge

Table of Contents

- What is a Metal Spring Side Hinge?

- Features of Metal Spring Side Hinges

- Applications of Spring Side Hinges

- Advantages of Metal Spring Side Hinges

- Tips for Choosing the Right Hinge

- Maintenance of Metal Spring Side Hinges

- Technological Advancements in Spring Side Hinges

What is a Metal Spring Side Hinge?

A metal spring side hinge is a mechanical component equipped with an integrated spring mechanism designed to enable the automatic closing of doors, windows, or other movable structures. Commonly referred to as a spring hinge, these hinges are widely used in both industrial and commercial settings. Metal spring side hinges ensure doors close automatically, providing safety and convenience. For instance, in fire doors, the spring within the hinge ensures the door remains closed, minimizing safety risks. Made from durable materials such as stainless steel, aluminum, or galvanized steel, these hinges can be designed to accommodate various load capacities and sizes. The spring mechanism can be customized based on the door’s weight and usage frequency, making them a versatile solution. Spring hinges are an essential part of modern architectural designs, offering both aesthetic and functional benefits. Additionally, these hinges contribute to energy savings and user-friendly features by preventing doors from staying open in climate-controlled environments, enhancing efficiency.

Features of Metal Spring Side Hinges

Spring hinges are designed with a range of features tailored for industrial, commercial, and residential applications. Firstly, these hinges are typically made from corrosion-resistant materials such as stainless steel, galvanized steel, or high-quality aluminum, ensuring longevity even in humid, outdoor, or harsh weather conditions. The spring mechanism is adjustable to suit the door’s weight, size, and usage frequency, providing an optimized experience in terms of convenience and safety. Some models offer bi-directional movement, allowing the door to open in both directions, which is particularly useful in high-traffic areas. Spring hinges stand out due to their low maintenance requirements and high durability. Their compact and sleek designs make them suitable for projects with aesthetic considerations. Furthermore, certain metal spring side hinges are certified for fire resistance (e.g., EN or UL standards), ensuring safety in emergency situations. Available in various finishes (chrome, matte, or polished), these hinges offer visual compatibility with different designs.

Applications of Spring Side Hinges

Metal spring side hinges play a critical role in a wide range of industries and applications. One of the most common uses is in fire doors found in commercial buildings and offices. These hinges ensure automatic door closure, meeting safety standards and reducing risks during emergencies like fires. In restaurants, cafes, and kitchens with high-traffic areas, spring hinges prevent doors from staying open, thereby improving energy efficiency and maintaining indoor temperatures. In hospitals, clinics, and healthcare facilities, metal spring side hinges are preferred to maintain hygienic environments by ensuring doors remain closed, controlling airflow. In residential projects, they are used in exterior doors, garden gates, or garage doors. In industrial facilities, heavy-duty spring hinges are ideal for high-load-capacity doors. High-traffic areas such as hotels, shopping malls, schools, and gyms benefit from these hinges, which provide both safety and ease of use. Additionally, in the maritime industry, corrosion-resistant metal spring side hinges are used on ships and yachts, offering high resistance to saltwater environments.

Advantages of Metal Spring Side Hinges

Metal spring side hinges offer numerous advantages to businesses and individual users. The automatic closing feature is a vital aspect of safety, eliminating the risk of doors remaining open during emergencies, such as fires or evacuations. Spring hinges reduce the need for manual closing, providing convenience for users, especially in busy environments. Their durable construction, made from stainless steel or aluminum, ensures long-term performance even in challenging conditions. Energy efficiency is a significant benefit, as these hinges prevent doors from staying open in climate-controlled spaces (e.g., cold storage or air-conditioned offices), leading to energy savings. Easy installation features save time and costs for both new projects and door retrofits. Low maintenance requirements further reduce operational expenses for businesses. Aesthetically, metal spring side hinges complement various architectural designs with modern and sleek finish options. Environmentally friendly manufacturing processes and recyclable materials make these hinges a sustainable choice. Moreover, their versatility, with models suited for different load capacities, ensures they meet diverse application needs.

Tips for Choosing the Right Hinge

Selecting a metal spring side hinge requires careful consideration of application needs, environmental conditions, and door specifications. First, determine the weight, size, and usage frequency of the door. Heavy doors require high-load-capacity spring hinges. Material choice is critical; for outdoor or humid environments, stainless steel or galvanized steel hinges are recommended for corrosion resistance. The spring tension affects the closing speed and force, so it should be chosen based on the application—soft-closing hinges are ideal for quiet environments like hospitals. Safety certifications, such as EN, UL, or ISO, are essential for hinges used in fire doors. Aesthetic compatibility should also be considered, with attention to the hinge’s finish (matte, polished, chrome) and color. The manufacturer’s technical support, warranty terms, and spare parts availability are crucial for long-term use. Additionally, when choosing a spring hinge, ensure ease of installation and compatibility with mounting equipment.

Maintenance of Metal Spring Side Hinges

Regular maintenance is essential for the longevity and efficient operation of metal spring side hinges. Hinges should be periodically inspected, with loose screws tightened and mounting integrity verified. Stainless steel hinges should be cleaned with a damp cloth and non-corrosive cleaners to prevent corrosion and maintain their aesthetic appearance. The spring mechanism should be regularly checked for signs of wear, deformation, or stiffening. Lubrication is critical to ensure smooth operation, but only manufacturer-recommended lubricants should be used. For safety, hinges used in fire doors must be tested regularly to verify spring tension. Hinges should be kept free of dust, dirt, or other particles to prevent buildup. Spring hinges should be protected from overloading and used in accordance with the door’s weight. Maintenance procedures must follow the manufacturer’s instructions and guidelines. In high-traffic areas, more frequent inspections are recommended.

Technological Advancements in Spring Side Hinges

The technology behind metal spring side hinges continues to evolve, offering innovative solutions for industrial, commercial, and residential applications. Smart spring hinges with Internet of Things (IoT) integration enable real-time monitoring and control of door movements, providing significant advantages in high-security settings, such as data centers or hospitals. Next-generation stainless steel alloys enhance hinge durability, offering greater resistance to corrosion, extreme temperatures, and mechanical stress. 3D printing technology accelerates the production of custom-designed metal spring side hinges, enabling adaptation to complex architectural projects. Energy-efficient spring mechanisms allow doors to close with less force and quieter operation, improving convenience and efficiency. Eco-friendly manufacturing processes, recyclable materials, and low carbon footprints prioritize sustainability in the spring hinge industry. Additionally, AI-powered hinges can analyze door usage data to predict maintenance needs and offer proactive solutions. These innovations meet the needs of both businesses and individuals, supporting the aesthetic, functional, and environmental requirements of modern structures.