Heat Barrier Aluminum Profile

Table of Contents

- What is a Thermally Insulated Aluminum Profile?

- How Does Thermal Barrier Technology Work?

- Applications of Thermally Insulated Aluminum Profiles

- Advantages of Thermally Insulated Aluminum Profiles

- Choosing the Right Thermally Insulated Aluminum Profile

- Installation and Maintenance Processes

- Technological Innovations in Thermally Insulated Aluminum Profiles

- Environmental Impacts and Sustainability

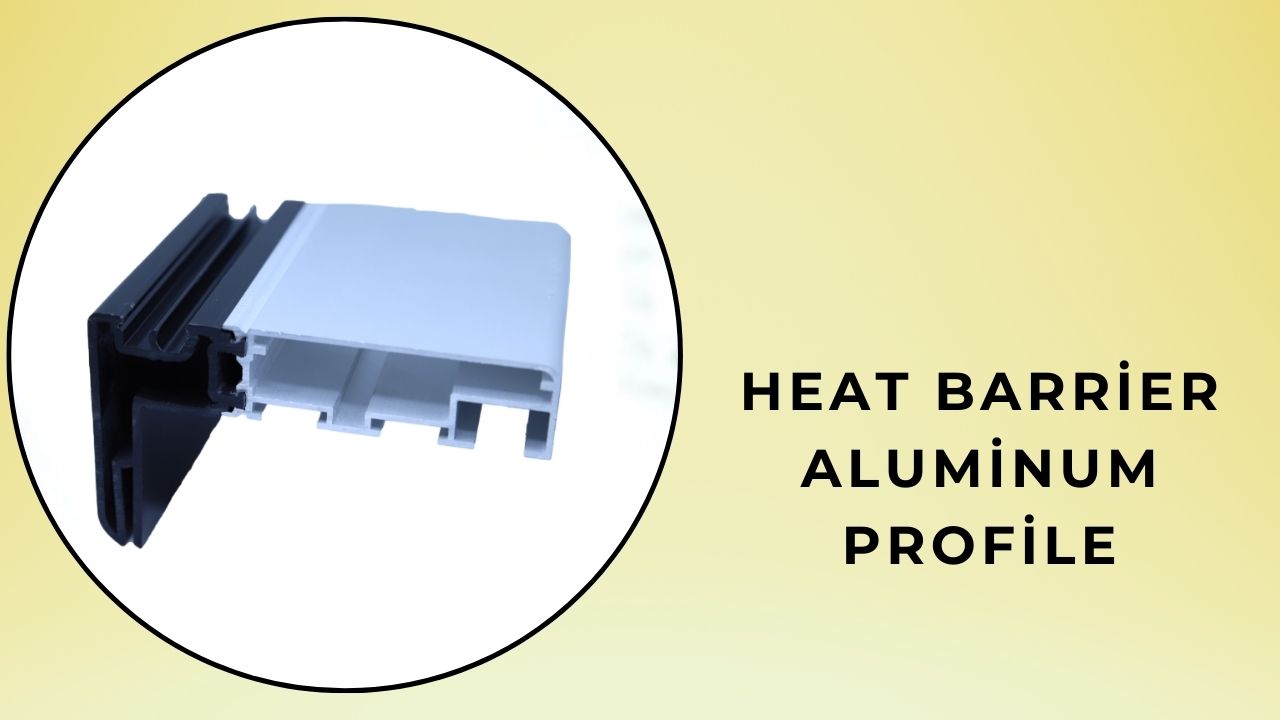

What is a Thermally Insulated Aluminum Profile?

A thermally insulated aluminum profile is a building material that combines the high strength and lightweight properties of aluminum with an energy-efficient thermal insulation technology. These profiles are typically manufactured by incorporating a polyamide barrier or similar insulating material between two aluminum sections. This barrier minimizes heat transfer between indoor and outdoor environments, thereby enhancing energy savings in buildings. The inherent durability and corrosion resistance of aluminum make these profiles a popular choice for both aesthetic and functional purposes. Thermally insulated aluminum profiles are widely used in window, door, and facade systems. Compared to traditional aluminum profiles, they offer superior thermal performance due to the thermal barrier. This reduces heating and cooling costs in buildings while creating a comfortable indoor environment. Additionally, these profiles provide aesthetic flexibility in modern architectural designs, as they can be customized with various colors and finishes. For instance, a thermally insulated aluminum profileused in the facade system of an office building not only ensures energy efficiency but also contributes to a sleek, contemporary appearance.

How Does Thermal Barrier Technology Work?

The core of a thermally insulated aluminum profile lies in an insulation barrier that interrupts aluminum’s high thermal conductivity. Aluminum naturally conducts heat quickly, which can lead to energy loss. However, materials such as polyamide strips or polyurethane fillers are used to separate the inner and outer sections of the profile, effectively breaking the thermal bridge. This barrier prevents the escape of warm or cool air, maintaining the indoor temperature. This technology plays a critical role in energy efficiency. For example, during winter, it helps retain indoor warmth, while in summer, it blocks external heat from entering. Polyamide barriers offer high strength and durability, ensuring the profile’s longevity. These barriers are also designed to accommodate the expansion and contraction of aluminum, preserving structural integrity. Advanced manufacturing techniques enable precise integration of these barriers into the profiles, maximizing thermal performance.

Applications of Thermally Insulated Aluminum Profiles

Thermally insulated aluminum profiles are used across a wide range of industries and applications. Their most common application is in building facade systems, window frames, and door frames. In modern architecture, these profiles are frequently chosen due to demands for energy efficiency and aesthetic design. For example, thermally insulated aluminum profiles used in the facade of a skyscraper provide both thermal insulation and contribute to the building’s modern aesthetic. In residential settings, thermally insulated aluminum profiles are employed in energy-saving window and door systems. These profiles maintain indoor warmth in cold climates and ensure a cool environment in hot climates. In commercial buildings, they are used in everything from office spaces to shopping malls. Additionally, they are preferred in industrial facilities for specialized projects requiring high durability. For instance, aluminum profiles used in the facade cladding of a factory building offer resistance to environmental conditions while reducing energy costs. In the healthcare sector, where hygiene is critical, such as in hospitals and laboratories, thermally insulated aluminum profiles stand out due to their cleanable surfaces and durability. In the transportation industry, they are used in the interior and exterior panels of vehicles like trains and buses. This broad range of applications highlights the versatilityand adaptability of these profiles.

Advantages of Thermally Insulated Aluminum Profiles

Thermally insulated aluminum profiles offer numerous advantages for both users and the environment. First and foremost, they provide energy efficiency. The thermal barrier significantly reduces heating and cooling costs in buildings. This is particularly valuable during periods of rising energy prices, offering an economical solution. Secondly, aluminum’s durability and resistance to corrosion make these profiles a long-lasting option. They are not susceptible to issues like rust or rot, which reduces maintenance costs. Additionally, their lightweight nature simplifies installation processes and reduces structural loads, which is especially beneficial in large-scale projects. From an aesthetic perspective, thermally insulated aluminum profiles offer design flexibility with various color and finish options. In modern architectural projects, these profiles provide both functional and visual contributions. Moreover, their recyclabilitysupports environmental sustainability goals. As aluminum can be recycled repeatedly, it is an eco-friendly choice.

Choosing the Right Thermally Insulated Aluminum Profile

Selecting a thermally insulated aluminum profile requires careful consideration of the project’s needs and environmental conditions. First, the profile’s thermal performance value (U-value) should be evaluated. A lower U-value indicates better thermal insulation, which is critical for projects where energy efficiency is a priority. Material quality is another key factor. The quality of the polyamide barrier or polyurethane filler directly impacts the profile’s long-term performance. Additionally, the type of coating (anodized, powder-coated, etc.) should be suitable for environmental conditions. For example, in a coastal project, a coating with extra corrosion resistance should be chosen. The project’s aesthetic requirements should also be considered. Thermally insulated aluminum profilescome in various colors and surface finishes, so the selection should align with the building’s overall design. Finally, the manufacturer’s warranty and technical support services are important criteria for long-term use.

Installation and Maintenance Processes

Proper installation of thermally insulated aluminum profiles directly affects the system’s performance and lifespan. The installation process varies depending on the profile’s design and the project’s requirements. Typically, profiles need to be precisely cut, assembled, and secured. During installation, accurate alignment is critical; otherwise, thermal performance may decrease, or structural issues may arise. In terms of maintenance, thermally insulated aluminum profilesrequire minimal upkeep. Aluminum’s corrosion resistance ensures long-term durability. However, regular cleaning prevents the buildup of dirt and dust on the surface. A soft cloth and a neutral cleaner should be used for cleaning. Abrasive chemicals or harsh materials can damage the coating. Additionally, the profile’s connection points and seals should be regularly inspected and replaced if necessary.

Technological Innovations in Thermally Insulated Aluminum Profiles

The technology behind thermally insulated aluminum profiles is constantly evolving to meet user needs and align with energy efficiency trends. In recent years, the use of smart insulation materials has increased. For example, next-generation polyamide barriers offer higher thermal performance while maintaining the same durability in thinner profiles. Digital manufacturing techniques have made customization easier. 3D modeling and CNC cutting technologies enable the precise production of complex designs. Additionally, nano-coatingsenhance the profiles’ corrosion resistance and aesthetic longevity. Integration with smart building systems allows these profiles to work with sensors or automated control mechanisms, optimizing energy management.

Environmental Impacts and Sustainability

Thermally insulated aluminum profiles offer significant advantages in terms of environmental sustainability. Aluminum’s recyclability makes these profiles an eco-friendly option. The use of recycled aluminum reduces energy consumption and the carbon footprint. Furthermore, the energy savings provided by these profiles further decrease the environmental impact of buildings. In manufacturing processes, the use of eco-friendly materials and energy-efficient technologies is becoming more widespread. For instance, low-carbon aluminum production makes the industry more sustainable. These features make thermally insulated aluminum profiles an ideal choice for environmentally conscious projects.