Frigo Lock

Table of Contents

- What is a Frigo Lock?

- Key Features of Frigo Locks

- Applications of Frigo Locks

- Benefits of Frigo Locks

- Tips for Choosing the Right Frigo Lock

- Installation and Maintenance of Frigo Locks

- Technological Innovations in Frigo Locks

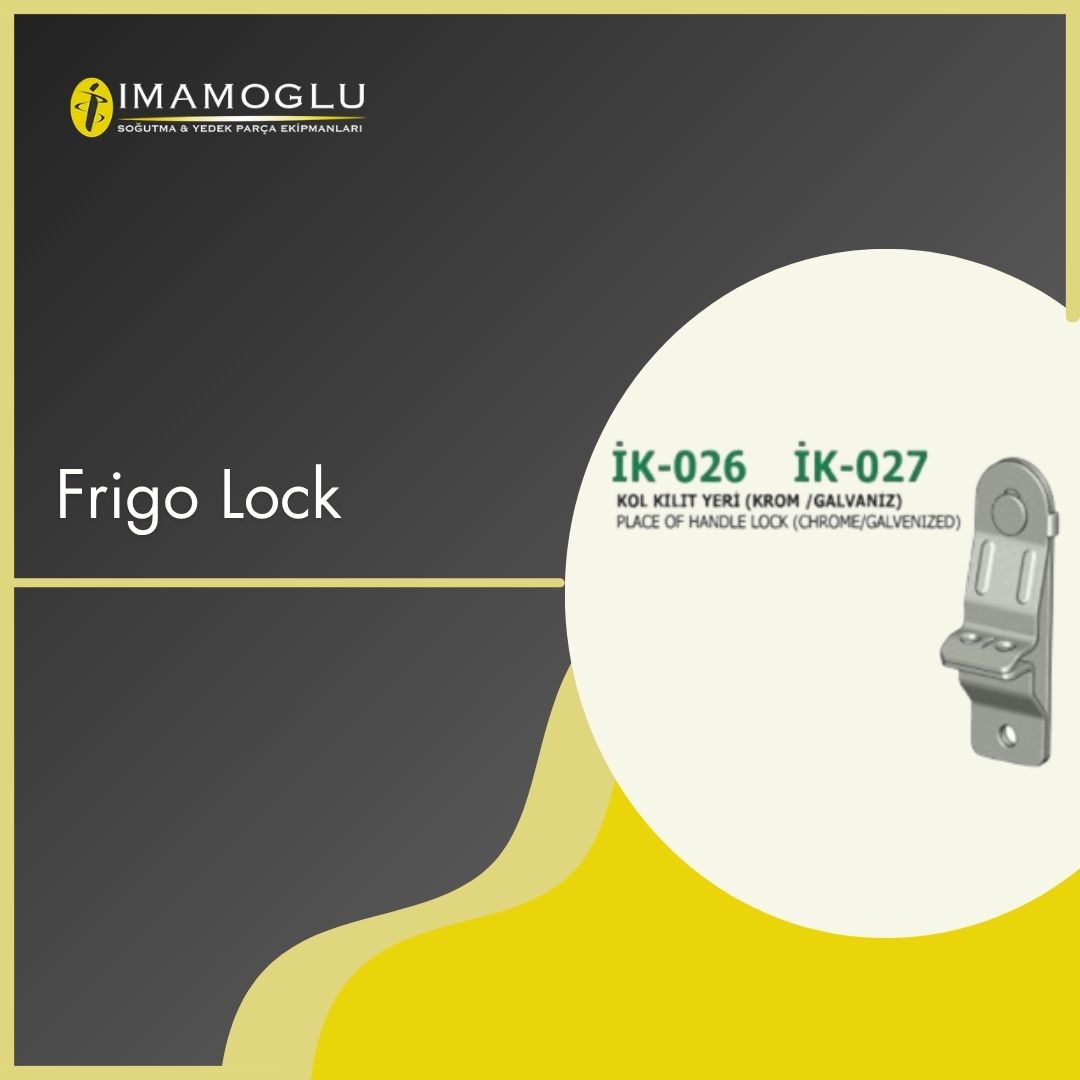

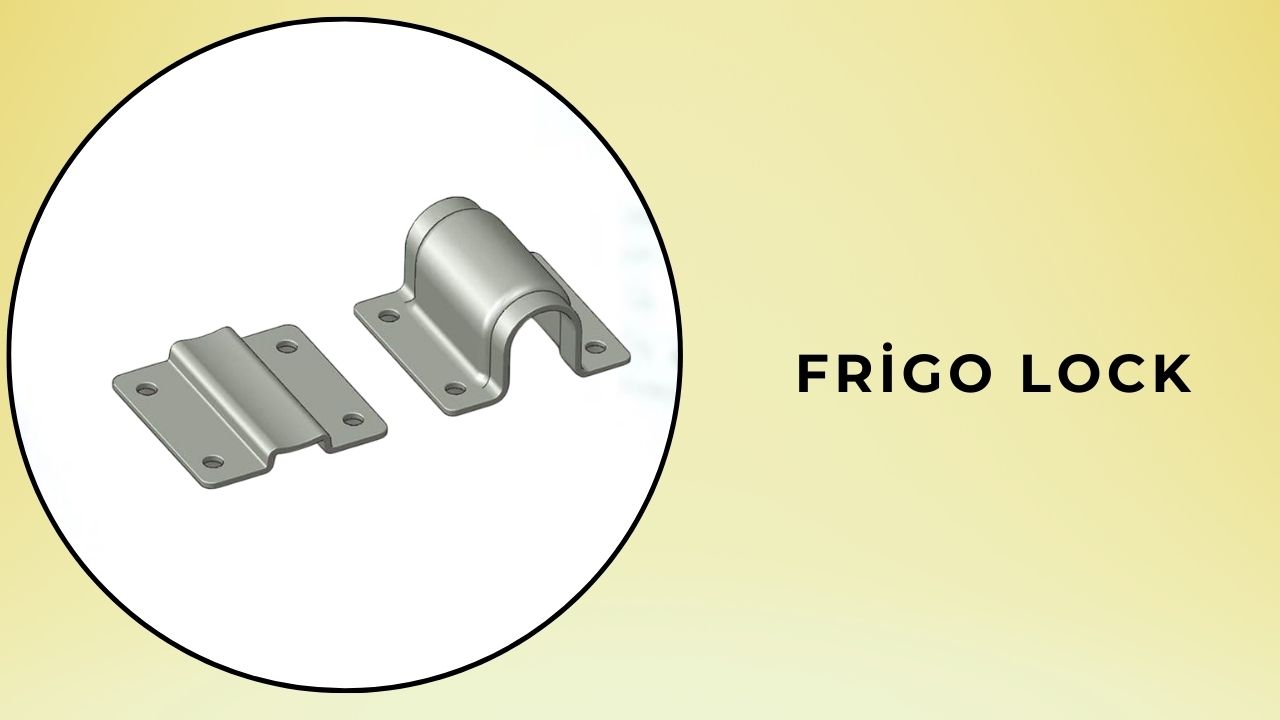

What is a Frigo Lock?

A frigo lock is a high-performance locking mechanism specifically designed for cold storage systems. These locks ensure safety and airtight sealing in low-temperature environments. Used in industries such as food, pharmaceuticals, logistics, and chemicals, frigo locks enable reliable closure of cold storage doors while enhancing energy efficiency. Typically made from stainless steel or corrosion-resistant alloys, frigo locks are designed to meet hygiene standards. Frigo locks ensure tight door closure, preventing heat loss and preserving the quality of stored products. They provide safety in harsh conditions, maintaining functionality even at extreme temperatures like -40°C. Their ergonomic designs make them user-friendly, with quick open-close mechanisms that boost operational efficiency. As an essential component of cold storage systems, frigo locks play a critical role in both energy savings and product safety.

Key Features of Frigo Locks

Frigo locks stand out with features tailored for demanding industrial conditions. Their durability comes from high-quality materials like stainless steel or special alloys, which resist corrosion and moisture, ensuring long-term performance. Designed for hygiene, frigo locks feature smooth surfaces that are easy to clean. Another key feature is the sealing performance of frigo locks. They ensure airtight closure of doors, maintaining temperature stability in cold storage units. Some models include safety-enhancing features, such as emergency release mechanisms to prevent entrapment. Ergonomic handles and mechanisms that function smoothly in low temperatures make frigo lockspractical to use. Modular designs allow compatibility with various door types, enhancing adaptability.

Applications of Frigo Locks

Frigo locks are widely used in industries relying on cold storage. In the food industry, they are essential for meat, dairy, fruit-vegetable, and frozen food storage, ensuring product freshness. Compliant with hygiene standards, frigo locks provide an advantage during food safety inspections. The pharmaceutical industry is another key area for frigo locks. In cold storage facilities storing vaccines, drugs, and biological materials, these locks maintain temperature control and safety. In logistics, frigo locks are used in cold chain transportation and storage to prevent product spoilage. The chemical industry employs frigo locksfor materials requiring low-temperature storage. They are also common in commercial settings like restaurants, supermarkets, and hospitals.

Benefits of Frigo Locks

Frigo locks offer both operational and economic benefits. They enhance energy efficiency by ensuring airtight closure, preventing cold air leakage from cold storage units, which reduces energy costs. Their durability eliminates the need for frequent replacements or extensive maintenance. In terms of hygiene, frigo locks excel with smooth, easy-to-clean surfaces, a critical advantage in food and pharmaceutical industries. Safety features, such as emergency release systems, protect both products and personnel. Ergonomic designs enable quick and easy operation, streamlining workflows. Environmentally friendly materials used in frigo lockssupport sustainability goals, while energy-efficient designs further lower operational costs.

Tips for Choosing the Right Frigo Lock

Selecting a frigo lock requires careful consideration of the facility’s needs and conditions. The lock’s material is a primary factor. Stainless steel locks are ideal for durability and hygiene, especially in humid or chemically exposed environments. The door type and size also matter, as sliding or hinged doors require different frigo lock models. Safety features should be evaluated. Emergency release mechanisms or anti-locking systems enhance cold storage safety. Hygienecertifications, such as FDA or EHEDG, are crucial for food and pharmaceutical applications. The lock’s performance in low temperatures, such as -40°C, must be verified to ensure reliability. Manufacturer support and warranty terms are also important for long-term use.

Installation and Maintenance of Frigo Locks

Proper installation of frigo locks is critical for their performance and durability. Installation should be performed by experts to ensure perfect alignment with the door. Sealing points must be carefully checked to prevent leaks. Improper installation can lead to heat loss or safety vulnerabilities. Maintenance is essential for the longevity of frigo locks. Regular hygiene practices keep locks clean. Stainless steel locks should be wiped with non-abrasive cleaners and dried with a soft cloth. Moving parts should be periodically lubricated with low-temperature-compatible lubricants to prevent freezing. The performance of locks in cold storageconditions should be routinely tested, and any wear or damage should prompt immediate repair or replacement.

Technological Innovations in Frigo Locks

Frigo lock technology continues to evolve to meet industry demands. Smart lock systems streamline cold storage management. RFID or Bluetooth-based frigo locks restrict access to authorized personnel, enhancing safety. Sensor integrations monitor whether locks are open or closed in real time, preventing energy loss. Nanotechnology-based coatings improve the hygiene performance of frigo locks by preventing bacterial and dirt buildup. 3D printing technology enables customized frigo lock production, ensuring compatibility with complex door designs. Eco-friendly materials and energy-efficient designs promote sustainability in the frigo lock industry. These innovations enhance operational efficiency while supporting environmentally conscious practices.