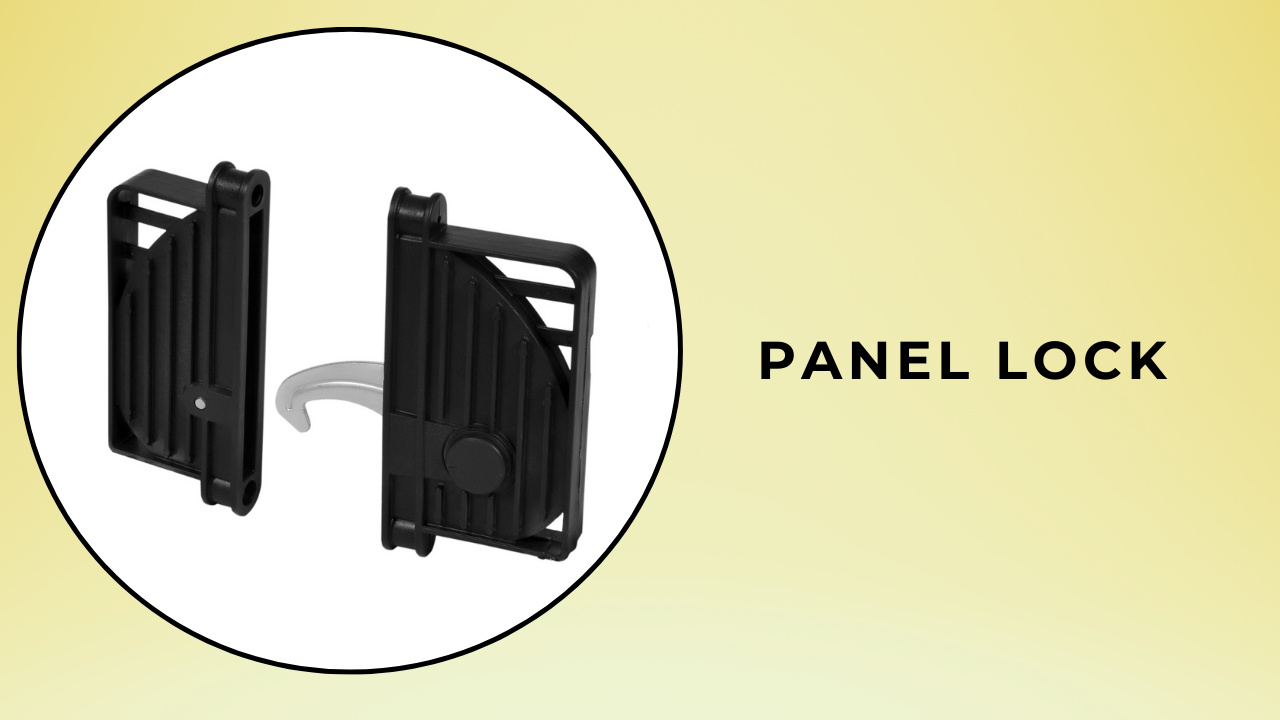

Cold Room Panel Lock

Purpose and Structure of Panel Locks

Cold room panel locks are specialized mechanisms designed to secure the connection points of sandwich panels used in cold storage and industrial refrigeration systems. These locks ensure a tight connection between panels, preventing air, moisture, and temperature leakage. In cold rooms, maintaining low temperatures and preventing energy loss are critical. Panel locks contribute to this process by providing airtightness and structural integrity, thereby enhancing the energy efficiency of the cold room.

Typically made from stainless steel, galvanized steel, or high-strength plastic, these locks are compatible with panel thicknesses ranging from 40 mm to 200 mm. Different lock types, such as eccentric, spring-loaded, or magnetic, are used in the walls, ceilings, or floors of cold rooms. These locks offer both ease of installation and long-lasting performance. For example, eccentric locks provide high airtightness, while spring-loaded locks are preferred for lighter applications.

Technical Specifications and Performance

Cold room panel locks are specifically designed to meet the high standards of refrigeration systems. Their main technical features include:

- Airtightness Capacity: Locks prevent air and moisture leakage at panel joints, reducing energy loss. Double-lock mechanisms enhance this performance.

- Corrosion Resistance: Materials like stainless steel or galvanized steel are resistant to corrosion in humid and cold environments.

- Quick Installation: Lock systems are designed for easy panel assembly, speeding up the installation process and reducing labor costs.

- Compatibility: They are compatible with various panel types (polyurethane, polyisocyanurate, rock wool) and thicknesses.

- Safety Features: Some locks are equipped with emergency exit mechanisms or safety locks, particularly preferred in medical storage facilities.

These features ensure that locks enhance the energy efficiency and reliability of cold rooms. For instance, locks used in a food storage facility play a critical role in maintaining consistent temperature conditions to prevent product spoilage.

Industrial Applications

Cold room panel locks play a significant role in various industries. Key application areas include:

- Food Industry: In cold rooms storing fresh, frozen, or shock-frozen food, locks ensure airtightness, preserving product freshness. For example, locks in frozen fish storage maintain airtightness at -18°C.

- Pharmaceutical and Medical Storage: Stable temperature conditions are essential for storing pharmaceuticals, vaccines, and sensitive medical supplies. Locks support these conditions and enhance product safety.

- Cold Chain Logistics: In cold chain transportation and storage facilities, locks prevent energy loss, ensuring product protection during transport.

- Commercial Kitchens and Retail: In restaurants, hotels, and supermarkets’ cold rooms, locks provide a hygienic and efficient environment. Locks used in service rooms are durable against frequent opening and closing.

Advantages of Panel Locks

Cold room panel locks offer various benefits to businesses and users:

- Energy Savings: Airtightness reduces the energy consumption of refrigeration systems, lowering operating costs. For example, up to 20% energy savings can be achieved in a cold room.

- Easy Installation: Modular lock systems enable quick and secure panel assembly, reducing project timelines.

- Hygiene Advantage: Tight connections prevent dust and moisture buildup, meeting hygiene standards in the food and pharmaceutical industries.

- Durability: Corrosion-resistant materials ensure long-term use even in harsh conditions.

- Flexibility: Lock solutions can be customized for different panel types and projects.

Production Process and Material Preferences

The production of panel locks requires precise engineering and quality control processes. The production stages are as follows:

- Design and Engineering: Lock design is tailored to the panel type, thickness, and airtightness requirements. 3D modeling enhances design accuracy.

- Material Selection: Materials such as stainless steel, galvanized steel, or rigid plastic are chosen. Stainless steel is preferred in hygienic environments, while plastic locks offer a cost-effective alternative.

- Manufacturing and Shaping: Locks are produced using casting, pressing, or injection molding techniques, with eccentric or spring mechanisms integrated.

- Surface Treatments: Locks undergo coating, passivation, or galvanization processes to protect against corrosion.

- Quality Control: Locks are tested for durability, airtightness, and ease of installation, ensuring compliance with international standards.

Material selection varies based on the intended use. For example, stainless steel locks are used in the food industry for hygiene, while galvanized steel locks are preferred in logistics warehouses.

Lock Types and Features

Cold room panel locks vary based on specific needs:

- Eccentric Locks: Rotating mechanisms that tightly connect panels, providing high airtightness, are used in large-scale cold rooms.

- Spring-Loaded Locks: Offering flexible connections, these are common in small-scale cold rooms.

- Emergency Exit Locks: Provide quick opening in emergencies, ideal for rooms with high safety requirements.

- Magnetic Locks: Supported by magnetic strips, these locks ensure tighter connections and enhance energy efficiency.

Installation and Maintenance Tips

Proper installation and regular maintenance of panel locks are essential for maintaining the performance of cold rooms. Recommendations include:

- Precise Installation: Locks must be perfectly aligned with panel dimensions to avoid airtightness issues.

- Expert Application: Installation should be performed by specialized teams, with checks to ensure proper lock functionality.

- Regular Cleaning: Lock mechanisms should be cleaned regularly with hygienic cleaners to prevent dust and moisture buildup.

- Mechanism Inspection: Mechanical parts should be periodically checked for wear or loosening and lubricated if necessary.

Production and Supply in Turkey

Turkey has a robust industry for the production of cold room panel locks. Notable manufacturers include:

- İmamoğlu Soğutma: Offers a wide range of eccentric and spring-loaded lock systems, serving both local and international markets.

İmamoğlu stands out in the industry with high-quality production and customer-focused services.

Innovative Solutions and Future Trends

Cold room panel locks are continually evolving with technological advancements. Future trends include:

- Smart Lock Technologies: Sensor-equipped locks can monitor airtightness, improving energy efficiency and notifying maintenance needs.

- Sustainable Materials: The use of recyclable steel and plastics reduces environmental impact and supports sustainability goals.

- Advanced Mechanisms: Next-generation eccentric and magnetic locks offer higher airtightness and ease of use.

Enhancing Lock System Performance

To optimize the performance of panel locks, the following strategies can be applied:

- Appropriate Lock Selection: Choose the lock type (eccentric, spring-loaded, or magnetic) based on project needs, such as high-strength locks for shock-freezing rooms.

- Periodic Testing: Regularly test lock airtightness to prevent energy loss.

- Spare Parts Inventory: Keep spare locks and components for quick replacements in case of wear.

- Staff Training: Train installation and maintenance teams on the proper use of lock systems.

- Automation Integration: Integrate locks with cold room control systems for automated monitoring and alerts.

- Preventive Maintenance Plans: Regular maintenance schedules for locks prevent failures and extend system lifespan.