Cold Room Door Seals

Definition and Function of Door Gaskets

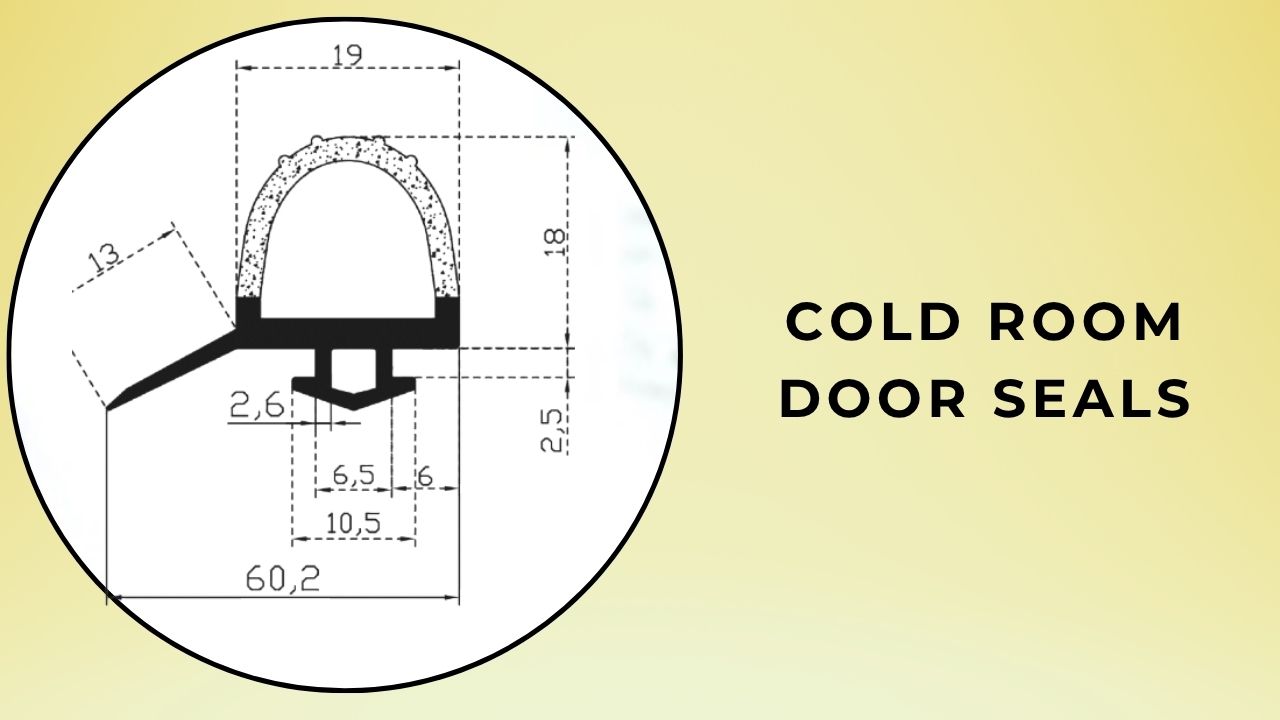

Cold room door gaskets are flexible rubber or silicone-based components used to ensure the sealing of doors in cold storage, industrial refrigeration systems, and similar environments. These gaskets close the gaps between the door and the frame, preventing air, moisture, and temperature transfer. In cold rooms, maintaining stable low temperatures and preventing energy loss are critical. Door gaskets play a fundamental role in this process by ensuring energy efficiency, hygiene, and product safety.

Gaskets are typically integrated into door frames or door panels and are designed to be compatible with various door types (sliding, hinged, service doors). Gaskets can adapt to door systems with panel thicknesses ranging from 60 mm to 200 mm.

Technical Specifications and Structural Advantages

Cold room door gaskets are specifically manufactured to meet the needs of high-performance refrigeration systems. Their main technical specifications include:

- High Sealing: Gaskets prevent air and moisture transfer, protecting the internal environment of the cold room. Double or triple gasket systems provide maximum sealing.

- Thermal Insulation: Thermal bridge-free designs prevent cold air from escaping and external heat from entering.

- Durable Materials: Typically made from EPDM rubber, silicone, or PVC, gaskets are resistant to low temperatures, UV rays, and chemicals.

- Flexible Structure: Designed to be compatible with different door types and frame profiles, offering a wide range of applications.

- Easy Replacement: Gaskets are designed for quick replacement in case of wear and for easy installation.

Application Areas and Industry Usage

Cold room door gaskets are critical components used in various industries. Their main application areas include:

- Food Storage and Processing: In cold rooms storing fresh, frozen, or shock-frozen food, gaskets ensure sealing to preserve product freshness.

- Pharmaceutical and Medical Product Storage: Vaccines, medicines, and sensitive medical supplies require specific temperature conditions. Gaskets support the continuity of these conditions.

- Cold Chain Logistics: In cold rooms used during transportation and storage, door gaskets prevent energy loss to maintain consistent temperatures.

- Commercial Kitchens and Retail: Service doors in restaurants, hotels, and supermarkets’ cold rooms are typically equipped with high-sealing gaskets.

Benefits of Door Gaskets

Cold room door gaskets offer multifaceted advantages to businesses and users:

- Energy Savings: High sealing capacity reduces the energy consumption of refrigeration systems, lowering operating costs.

- Hygiene Support: Smooth, easy-to-clean surfaces meet hygiene standards in the food and pharmaceutical industries.

- Long Lifespan: Durable materials resist low temperatures and frequent use, ensuring long-term performance.

- Flexible Application: Gaskets compatible with different door types and sizes offer customizable solutions.

- Easy Maintenance: Worn gaskets can be quickly replaced, minimizing maintenance costs.

Production Process and Material Options

The production of cold room door gaskets requires a precise engineering process. The production typically includes the following stages:

- Design and Sizing: Gasket design is created considering door type, frame profile, and sealing requirements.

- Material Selection: Materials such as EPDM rubber, silicone, or PVC are chosen. EPDM offers high resistance to low temperatures and chemicals, while silicone provides greater flexibility.

- Extrusion and Shaping: Gaskets are produced using extrusion techniques and shaped to fit door profiles.

- Surface Treatment: Gaskets may be treated with special coatings for UV resistance and corrosion protection.

- Quality Testing: Produced gaskets are tested for sealing, flexibility, and durability to ensure compliance with standards.

Material selection varies depending on the gasket’s intended use. For example, silicone gaskets provide a hygiene advantage in the food industry, while EPDM rubber is preferred for industrial applications.

Types of Gaskets and Their Features

Cold room door gaskets vary based on door type and usage requirements:

- Sliding Door Gaskets: Designed for sliding doors used in large cold rooms, these gaskets are compatible with rail systems and provide high sealing.

- Hinged Door Gaskets: Lightweight and flexible gaskets are used for hinged doors in small to medium-sized cold rooms.

- Service Door Gaskets: Practical and durable gaskets are preferred for service doors in industrial kitchens and retail settings.

- Magnetic Gaskets: Equipped with magnetic strips, these gaskets ensure tighter door closure and reduce energy loss.

Installation and Maintenance Guide

Proper installation and regular maintenance of door gaskets ensure long-lasting performance. Key recommendations include:

- Correct Installation: Gaskets must be precisely fitted to the door and frame dimensions. Incorrect installation may lead to sealing issues.

- Professional Application: Installation should be carried out by expert teams to ensure proper gasket placement.

- Routine Cleaning: Gaskets should be regularly cleaned to prevent dirt and moisture buildup. In the food industry, hygienic cleaners should be used.

- Wear Inspection: Gaskets should be regularly checked for wear and tear and replaced as needed.

Gasket Manufacturers and Supply in Turkey

Turkey has a strong industry for cold room door gasket production. Some prominent manufacturers include:

- İmamoğlu Soğutma: This company produces EPDM and silicone-based door gaskets, offering a wide range of products.

İmamoğlu serves both local and international markets and promotes its products through detailed catalogs.

Technological Developments and New Trends

Cold room door gaskets are continuously evolving with technological innovations. Future trends include:

- Smart Gasket Systems: Sensor-equipped gaskets can automatically monitor door sealing and optimize energy efficiency.

- Eco-Friendly Materials: The use of recyclable rubber and silicone contributes to sustainability goals.

- Advanced Sealing Technologies: Next-generation magnetic and multi-layered gaskets can offer higher insulation performance.