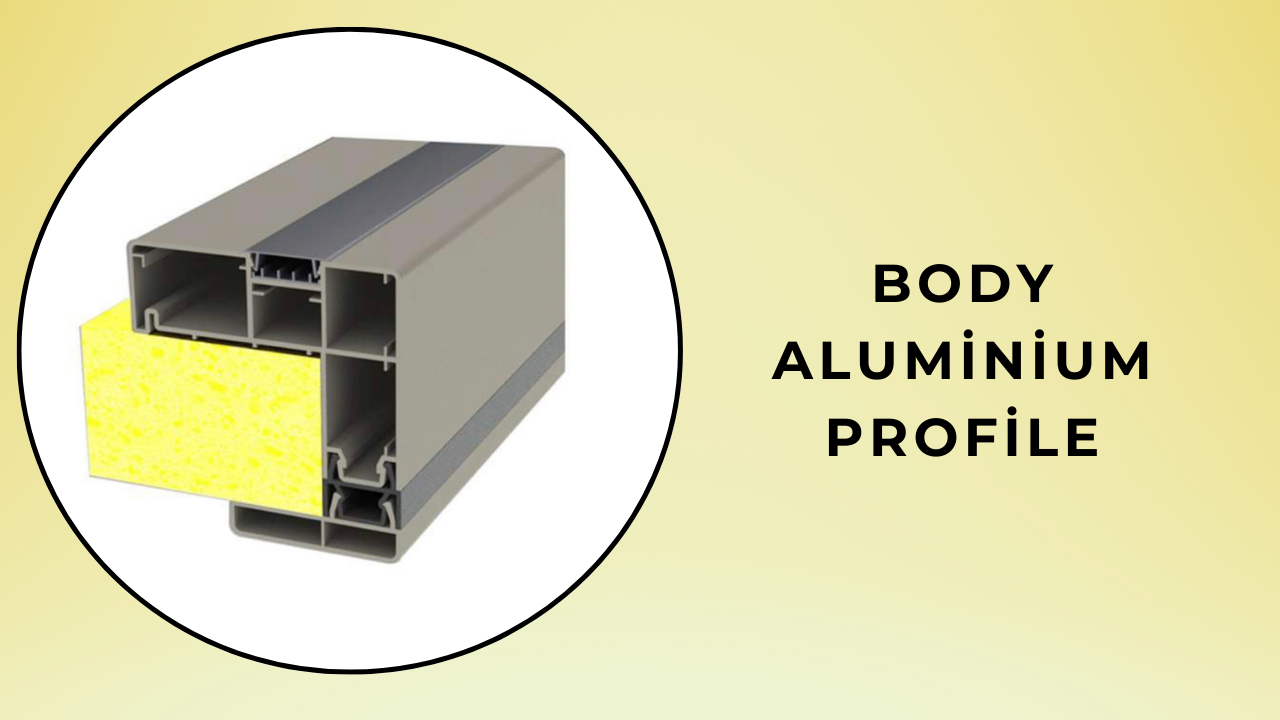

Body Aluminum Profile

What is Body Aluminum Profile?

Body aluminum profiles are profiles made of aluminum, a light and durable material used in the automotive industry and generally preferred in the production of external structural components of vehicles. These profiles are used in the creation of automobile bodies, chassis systems and other structural elements. Body aluminum profiles have features that reduce the total weight of the vehicle, increase its safety and improve its performance. Thanks to its lightness and durability, aluminum has become one of the indispensable materials of the automotive industry.

Aluminum is also a preferred material, especially in automobile parts that are exposed to external factors, because it is resistant to corrosion. In this way, vehicles last longer and maintenance costs are reduced. Body aluminum profiles not only offer an aesthetic appearance but also increase environmental sustainability. Automotive manufacturers who want to ensure both energy efficiency and be environmentally friendly use these profiles to provide advantages in terms of both performance and the environment.

Main Features of Body Aluminum Profile

Body aluminum profiles are known not only for their lightness but also for their durability. The key properties of this material are critical to improving high efficiency and safety in automotive manufacturing.

Lightness

Aluminum provides one of the indispensable features of the automotive industry: lightness. Compared to other metals, aluminum has a much lower density. This allows vehicles to be lighter. Light vehicles provide more efficient fuel consumption and reduce environmental impact. Additionally, thanks to its lightness, the vehicle gains advantages in acceleration, braking and general driving dynamics. Especially in vehicles where energy efficiency is important, such as electric vehicles, the light weight properties of aluminum improve performance and battery life.

Durability and Strength

Aluminum is a very durable and strong material, as well as being lightweight. These features make them ideal for using aluminum profiles in automobile body and chassis production. Aluminum ensures the safety of the vehicle by increasing the energy absorption capacity of the chassis and body in the event of a collision. At the same time, it is resistant to harsh weather conditions, road salt and chemical effects. This ensures that the exterior of the vehicle lasts for a long time and remains safe without corrosion.

Easy Processability

One of the biggest advantages of aluminum is that it is easy to process. Aluminum is an extremely suitable material for processes such as welding, cutting, shaping and assembly. This feature allows manufacturers to create designs even in complex geometric shapes. Body aluminum profiles allow vehicle design to be more flexible and creative. Additionally, processing aluminum generally requires less energy, reducing production costs.

Thermal and Electrical Conductivity

Aluminum is a material with high thermal and electrical conductivity. This feature is useful for optimizing the vehicle's thermal management. The thermal conductivity of aluminum is used especially for temperature control and efficient operation of electronic systems in the engine compartment. The conductivity properties of aluminum are critical for the efficient operation of battery management systems in electric vehicles. Aluminum is used in electric vehicles to prevent batteries from overheating and to activate cooling systems.

Eco-Friendly

Aluminum is a recyclable material, making it an environmentally friendly option. Body aluminum profiles can be made using recycled aluminum in production processes. This ensures more efficient use of natural resources and less waste. Recycling aluminum saves energy and reduces the carbon footprint. This environmentally friendly approach contributes to achieving the automotive industry's sustainability goals.

Usage Areas of Body Aluminum Profile

Body aluminum profiles are used in many different areas in the automotive industry. These profiles play a critical role in creating the exterior structure of vehicles, increasing safety and ensuring fuel efficiency. Below are some of the common uses of bodywork aluminum profiles:

Automobile Body

Aluminum profiles are widely used, especially in automobile body production. Aluminum is used in parts of vehicles such as chassis, doors, roof and bumpers. This material strengthens the exterior structure of the vehicle while also making it lighter. Aluminum also gives the vehicle a stylish appearance and allows the application of modern designs. Automobile manufacturers can meet the aesthetic and functional requirements of vehicles by using aluminum profiles.

Electric Vehicles

Electric vehicles have higher efficiency and performance requirements than conventional vehicles. Aluminum is an ideal material used in the production of electric vehicles. Aluminum profiles are used in battery carrying systems, chassis structures and other critical components of electric vehicles. While aluminum makes electric vehicles lighter, it also helps cooling systems operate effectively, which increases battery life. Additionally, it increases the efficiency of electric vehicles, providing range and energy savings.

Vehicle Chassis

Aluminum is also used in the production of vehicle chassis. Aluminum chassis form the basic structure of the vehicles and carry all other components. The lightweight aluminum chassis reduces the overall weight of the vehicle and improves driving dynamics. Additionally, aluminum's energy absorption capacity increases safety in the event of a crash. Aluminum chassis enables the design of vehicle structures that are made stronger and more durable.

Interior Components

Aluminum is used not only in the exterior bodywork but also in interior components. In particular, the steering wheel, console, seats and other interior structural components are made of aluminum. This increases the lightness and durability of the vehicle's interior, while also giving it a stylish appearance. Aluminum profiles play an important role in interior design because they are an important component in terms of comfort and aesthetics inside the vehicle.

Security Systems

Aluminum is also used effectively in vehicle security systems. Aluminum is used to ensure the safety of vehicles as it has the capacity to absorb energy in the event of a collision. Aluminum's durability and flexibility are critical in safety components such as airbags and crash systems. Thanks to aluminum profiles, these systems work more efficiently during a collision and increase the safety of passengers.

Advantages of Body Aluminum Profile

Body aluminum profiles provide many advantages in the automotive industry. These advantages offered by aluminum enable vehicles to be lighter, durable, safe and environmentally friendly.

Weight Reduction

Aluminum profiles allow for improved performance while reducing the overall weight of vehicles. Lighter weight of vehicles increases fuel efficiency and reduces the impact on the environment. Additionally, lighter vehicles accelerate faster and the effectiveness of their braking systems increases.

Durability and Safety

Aluminum is an important material that increases the durability of vehicles. Aluminum bodies are resistant to corrosion and external factors and provide long-lasting use. Additionally, the energy absorption properties of aluminum profiles increase safety in the event of a collision.

Easy Processability

Aluminum is easy to machine, providing manufacturers with design flexibility. Complex shapes can be produced and assembly processes can be completed quickly. Additionally, processing aluminum consumes less energy, which reduces production costs.

Eco-Friendly

Aluminum is a recyclable material, making it an environmentally friendly option. Reducing waste and recycling helps the automotive industry achieve its sustainability goals.